[youtube https://www.youtube.com/watch?v=ZqRbc_0SaVs?feature=oembed&w=100&h=100]

The world has a plastic problem. According to the United Nations, upward of 8 million tons of plastics makes its way into the oceans each year. Exactly how you get rid of this has been the subject of plenty of investigation. Efforts have focused on everything from reducing the use of plastics in packaging to using drones to help spot plastic-clogged waterways from the sky. Researchers from Purdue University have a different idea, however: They want to turn it into fuel.

To achieve this, they have pioneered a new chemical conversion process, capable of converting more than 90 percent of polyolefin waste — the polymer behind widely used plastic polyethylene — into high-quality gasoline or diesel-like fuel. The results could be a game-changer.

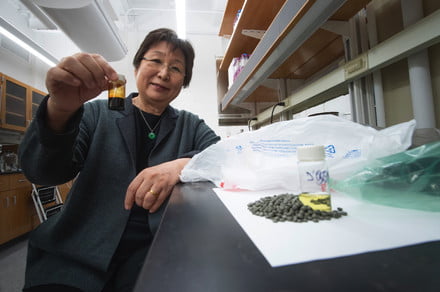

“We have developed a method to convert polyolefin waste, which include Type 2 (HDPE), Type 4 (LDPE and LLDPE), and Type 5 (PP), into various useful products,” Nien-Hwa Linda Wang, a professor in Purdue’s Davidson School of Chemical Engineering, told Digital Trends. “The conversion is achieved using subcritical or supercritical water, which can convert plastic waste into oil, fuels, or gas, depending on the processing conditions. Some impurities in the plastic waste is converted into oil or extracted into the processing water. Both conversion and extraction are achieved in the same process.”

To carry out their process, the researchers heated water up to extremely high temperatures of around 850 degrees Fahrenheit under high pressure. When the purified plastic waste was added to the supercritical water, it transformed into oil after a process lasting upward of an hour.

Wang said that she sees no reason why this laboratory demonstration should not be turned into an economical large-scale process — although there’s still more work to be done.

“We have [had] great success for converting polyolefin waste,” Wang said. “Further research is still needed to produce higher quality products with lower processing costs for the polyolefin waste. We have not yet had any research funding to test this technology for converting other types of plastic waste or for converting complex waste mixtures. We hope to raise funding to test this technology at a pilot scale. Successful results at pilot scale will motivate industry to commercialize this technology.”

A paper describing the work was recently published in the journal Sustainable Chemistry and Engineering.

Editors’ Recommendations

- Water-based fuel cell converts carbon emissions to electricity

- Magical new nanotube-infused fabric cools you in summer, warms you in winter

- Microsoft’s friendly Xiaoice A.I can figure out what you want — before you ask

- Researchers discover a way to make 3D printing 100 times faster using light

- How to deep fry a turkey