There’s currently a struggle between two very different 3D printing technologies, known as FDM (Fused Deposition Modeling) and advanced SLA (Stereolithography). The two methods are very, very different, but they are both likely to stick around the 3D printing world. Each has its own important strengths and applications.

However, if you’re buying or learning how to use a 3D printer, it’s vital to understand the difference between FDM and SLA—so we’re going to talk about it!

Note: There are other types of 3D printing as well, such as polyjet and SLS. WE talk more about these in our comprehensive 3D printing piece. However, FDM and SLA tend to be more common, especially at the consumer market level, so we want to take a closer look at them specifically.

FDM (Fused Deposition Modeling)

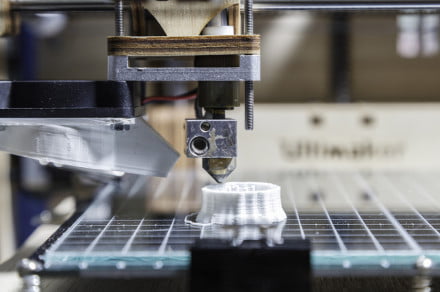

If you watch a video of a 3D printer at work, you are likely to see a carefully programmed printing nozzle in a three-dimensional space, extruding a line of molten plastic to sketch out a clear shape. It’s a very popular image, and FDM is the most popular technique used by small 3D printers. It creates small layers that bond together to ultimately create an object. Let’s talk about how that works.

First, the printer has to be given the right information – essentially, a path to follow so that the deposited material will create the right object. This is done using a 3D model file like an STL or OBJ file, which contains information about how an object is “sliced” into layers that the FDM can apply one at a time. This is one of the simplest ways to program at 3D object, and you can use it for many different kinds of objects. Of course, the more complex or small the object, the finer it has to be sliced, and not all FDM printers are equipped to deal with complex objects.

With the file on the object layers sent to the printer, it has all the data it needs to get started. However, it still needs raw materials. The printer uses filaments made from raw materials that can be heated up and easily pushed out into ropes or threads. Typically the material is made of easily molded, relatively safe plastic—but there’s a lot of variance in filaments, which can also be combinations of other materials to give the printed object additional properties.

Following the 3D file, the printer now heats the materials and extrudes through the nozzle as it moves, one layer at a time. When finished, there’s usually a brief waiting time so that the layers can fully bond with each other. Then the object is ready to be used!

What it’s good for

- Home 3D printers: FDM printers tend to be very affordable, relatively easy to operate, and their materials are widely available.

- FDM has gotten more precise: FDM is easy to scale to more complex objects.

- Durability: FDM printed objects can be used for a variety of purposes, and improved filaments continue to make them more durable.

- Learning 3D printing: FDM is a great place to start when teaching students, learning how to code for 3D printing, or using your own 3D printer.

FDM negatives

FDM printers struggle with particularly fine detail, or objects that need moving parts, etc. It can’t really create high-end prototypes. They can also be quite finicky. The coding and calibration have to be very precise, or the printer won’t work correctly. This might mean that you have to do a lot of work to “teach” the printer how to start making a new object.